| Last updated date: |

|---|

| 22 August 2025 |

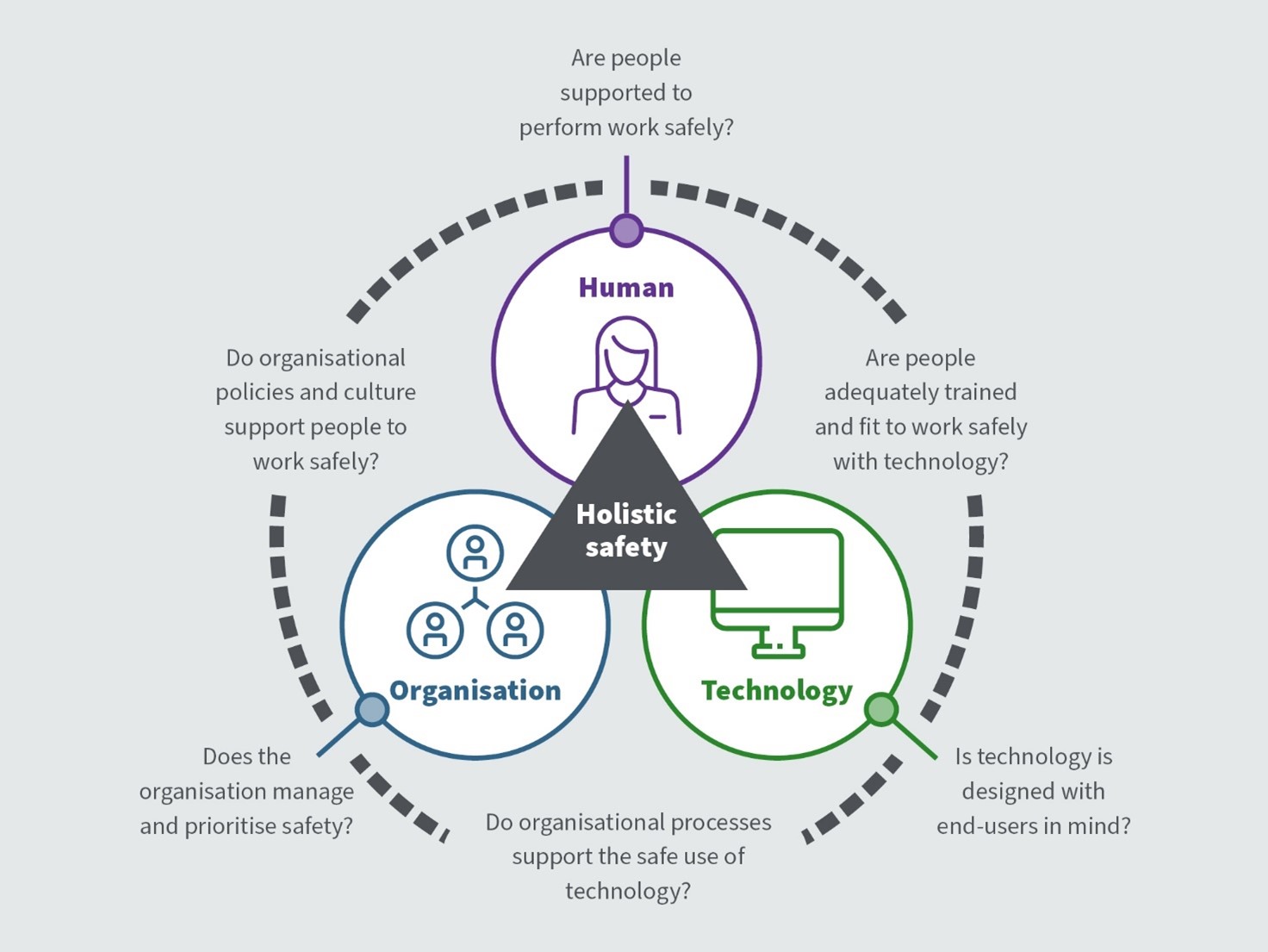

This document provides guidance to licence holders on the interaction of key technological, individual or human, and organisational factors necessary to create and maintain optimal safety.

Introduction

Citation

This publication may be cited as the Regulatory Guide: Holistic Safety (2025). This publication supersedes the Regulatory Guide - Holistic Safety (ARPANSA-GDE-1753).

Background

Charged with the function of protecting the health and safety of people and the environment from the harmful effects of radiation under the Australian Radiation Protection and Nuclear Safety Act 1998 (the Act), ARPANSA adopts a holistic safety approach to the regulation of radiation protection and nuclear safety.

A holistic safety approach considers the role of the whole system in managing safety. This includes technical (equipment, tools, technology, etc.), human (cognition, attention, perception, etc.) and organisational (culture, procedures, work environment, etc.) factors, as well as the interactions between them.

Figure 1: Holistic safety is an interaction between technical, human, and organisational factors (THOF)

Holistic safety also takes a systems-thinking approach which recognises that work exists within a wide system, where safety responsibility and influence spans multiple system levels (Salmon et al., 2023). These levels include the work itself, the staff who perform the work, the leaders (both middle and senior management) who manage the work, the organisation commissioning the work, and external stakeholders (including regulators; Rasmussen, 1997).

ARPANSA encourages the adoption of holistic safety principles. This requires a comprehensive understanding of factors affecting the safety of day-to-day work, especially those that may otherwise be overlooked. This approach aims to prevent the decline of safety performance, in line with International Nuclear Safety Advisory Group (INSAG) Report 15.

Figure 2: Information and influence should move across all levels of a system hierarchy, and in both directions.

Development of the Guide

This Guide has been developed in consultation with ARPANSA’s international nuclear regulator counterparts, Australian regulators in other high-risk industries, and ARPANSA licence holders.

These guidelines are consistent with the aims of:

- international best practice on nuclear safety, including the International Atomic Energy Agency’s (IAEA’s) General Safety Requirements Part 2 – Leadership and Management for Safety and IAEA working document A Harmonized Safety Culture Model

- international standards established by the International Organization of Standardization (ISO) and Nuclear Energy Agency (NEA)

- academic publications on systems-thinking and safety science, including seminal papers on accident precursors and accident causation models (Dekker, 2011; Hollnagel, 2010; Salmon et al., 2023; Taylor et al., 2015).

Wherever possible, these references have been provided alongside their relevant factors within this guide.

Purpose

The purpose of this Guide is to provide ARPANSA applicants, licence holders, assessors, and inspectors an updated framework on holistic safety in line with modern best practice. When implemented, these guidelines should support applicants and licence holders in meeting their regulatory requirements, including sections 53(ea), 54(ea), 57A and 60 of the Australian Radiation Protection and Nuclear Safety Regulations 2018 (the Regulations).

A secondary objective is to provide reference to high quality standards and research to assist in the practical application of this Guide. These resources can be used to assess systems and operations, develop internal assessment tools, and integrate holistic safety across organisations.

Scope

This Guide presents a high-level overview of what should be considered when taking a holistic approach. As a guide, the individual recommendations within this document are not regulatory requirements but instead establish ARPANSA’s regulatory expectations for best practice and inform ARPANSA’s approach to making licensing decisions (Act s32(3) and s33(3)).

ARPANSA is the Australian Government’s primary authority on radiation protection and nuclear safety. As such, all factors in this Guide are considered with respect to radiation protection and nuclear safety. Factors in this Guide may overlap with those considered by other regulators (e.g. Comcare). Licence holders should be aware that regulators may take different approaches to these factors due to differences in underlying legislation and jurisdiction.

A graded approach should be adopted by licence holders in the consideration and application of these factors, where the scale of actions taken is proportional to the significance of the associated risk. Licence holders should apply due consideration to the relevance of each factor and ensure alignment with international best practice and other applicable documents.

How to use this Guide

How licence holders should use this Guide

This Guide is designed to be a practical and enabling resource for the application of holistic safety throughout the work lifecycle (e.g. when designing systems, developing procedures, or conducting self-assessments).

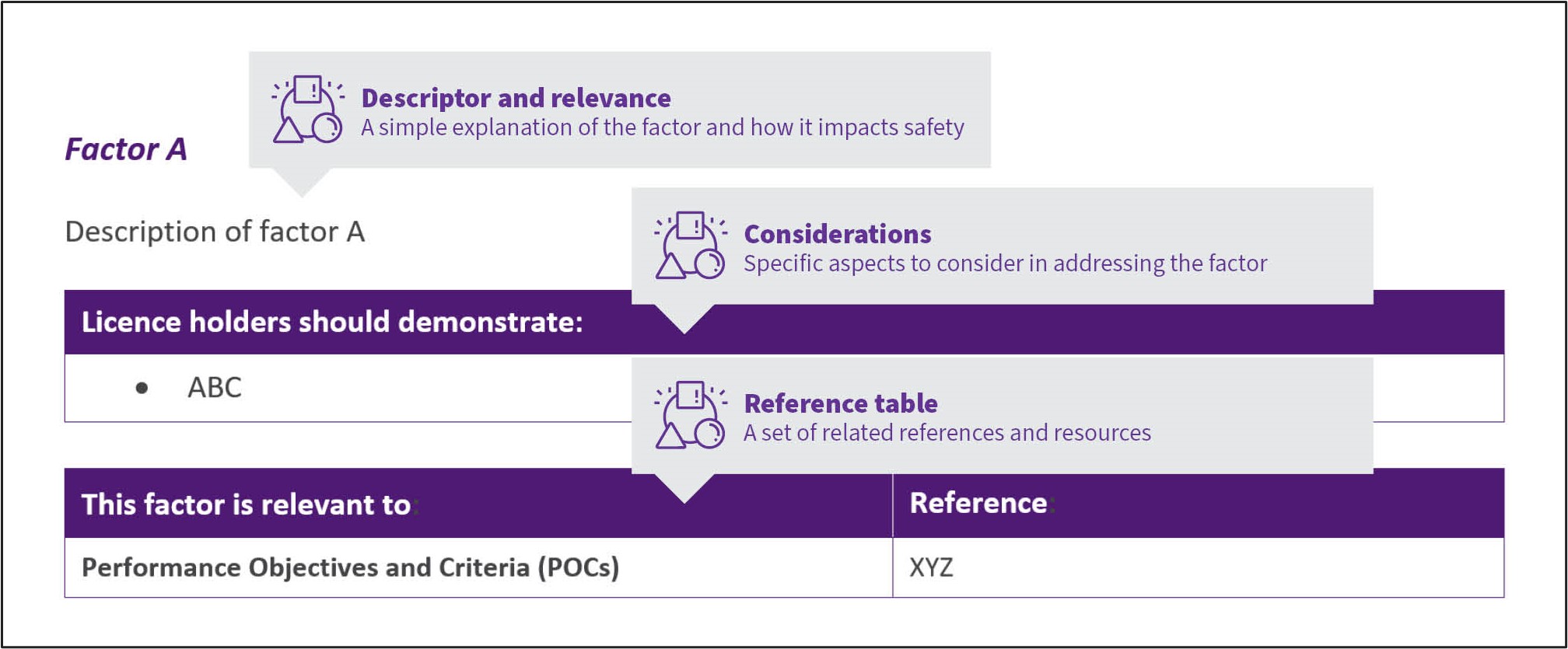

The Guide is divided into 4 chapters: Technical Factors, Human Factors, Organisational Factors, and Systemic Factors. Each chapter includes a number of factor categories (e.g., Defence in Depth, Situation Awareness, Work Environment, etc.), which each contain factors. Each factor follows a set structure:

Licence holders are encouraged to reflect on the relevance and prevalence of each factor in their respective work/workplace. Once relevant factors are identified, licence holders should reflect on the individual considerations and interrogate how effectively those considerations are being addressed by their organisation. Licence holders should also determine where improvements are required and should develop specific action plans to achieve them. Reference tables should be used as additional support in developing actions.

Where factors have been deemed less/not relevant, licence holders should justify reasons for exclusion. Where reference tables contain a limited number of resources, this should not be interpreted as an indication of the factor's limited relevance. Instead, it underscores the unique value of this document, which extends beyond the scope of factors addressed by other resources. Finally, reference tables are not exhaustive lists of related standards, codes, legislation, or best-practice.

The framework provided in this Guide should become part of a licence holder’s process for designing, implementing and assessing holistic safety in their systems, equipment, tools, tasks and general work environments. This Guide can also be used to inform investigations into incidents and other safety events.

Licence holders should adopt a systematic approach to the application of the factors within this framework and understand how the factors across the 4 chapters interact across the system. When implemented thoughtfully, selected controls and actions can be designed to support multiple factors at once.

How ARPANSA will use this Guide

This Guide is ARPANSA’s principal document on holistic safety. It will serve as the main point of reference for ARPANSA’s regulatory approach, particularly sections 53(ea), 54(ea), 57A and 60 of the Regulations. This includes in the assessment of licence holder submissions and in conducting inspections.

ARPANSA adopts an evidence-based approach to regulation. Any decisions made by ARPANSA will reflect the data collected from/submitted by licence holders, in line with a graded approach. Where evidence points to issues regarding holistic safety, this may prompt further enquiry.

Chapter 1: Technical factors

Technical factors are the set of technological and protective conditions that support operators in being safe. This chapter outlines the importance of distinct technical factors and their safety relevance.

Licence holders should demonstrate a concerted effort in addressing these factors when designing and implementing technology and related controls, including the unique interactions introduced by these technologies.

Technical factors are relevant wherever humans interact with technology. While these factors are particularly significant for human-operated technologies, all technology requires some degree of human involvement and organisational support in its design, development, monitoring, maintenance, and decommissioning. Consideration of technical factors, and their interactions with human and organisational factors, throughout each stage will support safety for all degrees of human involvement.

Technology factors

Technology integrations in the workplace can result in unique and unexpected interactions between systems and the people working with them. The factors in this category address the safety implications that may arise from the intersection of technology and the way work is fundamentally performed.

Human-machine interfaces

Human-machine interfaces (HMIs) are the point of interaction between a human and a machine. This includes where the machine provides information on its status (output) and where an operator engages with the machine (input). These interfaces can include the user interface of a computer, analogue dials, control panels, etc. Good HMIs support users in making safe decisions by providing accurate and timely information in an intuitive, responsive and easy-to-understand format.

| Licence holders should demonstrate: |

|

| This factor is relevant to: | Reference: |

| Performance Objectives and Criteria for facilities (POCs(F)) | C17.3, C21.10 |

| General Safety Requirements (GSR) Part 2 | 2.2b |

| Australian or International Standards (AUS/INT STDs) | ISO 6385:2016, ISO 9241 (multiple parts) |

Note: criteria listed from Performance Objectives and Criteria (facility) in reference tables may differ from matched criteria listed in Performance Objectives and Criteria (sources). Readers will need to compare documents to determine relevant criteria.

Automation and artificial intelligence

Integration of automation (including semi-automation) and artificial intelligence (AI) into systems involves the transition from ‘humans as controllers’ to ‘humans as system managers’. As the complexity of automation and algorithms grows, so too does the challenge of deciphering the system's internal logic. This has implications for how individuals interact with systems, including how they assess risk, what decisions they make, and what actions they take. Outcomes can be either beneficial (e.g. system efficiency) or adverse (e.g. overconfidence in automated functions or impeded situation awareness) to safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| GSR Part 2 | 4.30, 4.31, 4.32 |

| AUS/INT STDs | ISO/IEC 42001:2023, ISO/IEC TR 24027:2021, Australian Government Voluntary AI Safety Standard |

Control factors

Applying control measures, in a graded approach, is crucial for protecting safety and security. The following factor(s) address the way in which controls should be designed, selected and layered to provide maximum safety assurances.

Defence in Depth

Defence in depth (DiD) refers to the deployment of successive levels of protection, and is traditionally applied to nuclear safety. However, elements of DiD can be applied to safety generally. Specifically, DiD seeks to:

- compensate for potential failures (technical, human or organisational)

- provide, and maintain the effectiveness of, protective barriers

- protect the public and the environment when protective barriers are ineffective.

DiD, as presented in INSAG-10, is structured in five levels. If one level fails, subsequent levels should take effect. Importantly, conservative design, quality assurance and a mature safety culture are considered prerequisites to the effective implementation of DiD.

Level | Objective | Essential means |

|---|---|---|

1 | Prevent failures and ensure that anticipated operational occurrences/disturbances are infrequent | Conservative, high quality, proven design and high quality in construction |

2 | Maintain the intended operational states and detect failures | Process control and limiting systems, other surveillance features and procedures |

3 | Protect against design-basis accidents | Safety systems and accident procedures |

4 | Limit the progression and mitigate the consequences of beyond-design-basis accidents | Accident management and mitigation |

5 | Mitigate the radiological consequences of beyond-design-basis accidents | Off-site emergency response |

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C17.5, C21.9, C33.10, C34.2, C34.4, C37, C38 |

| Other IBP | IAEA: INSAG-10; GSR Part 4 Safety Assessment for Facilities and Activities, Requirement 13; SRS No. 46 |

Chapter 2: Human factors

Human factors are the full array of complex mental, physical and psychosocial factors that contribute to an individual’s ability to work safely. This chapter outlines the importance of distinct human factors and their relevance to nuclear safety and radiation protection.

Licence holders should demonstrate consideration and integration of these factors when designing equipment, tools, tasks and the general work environment. This includes understanding how people think and feel, how they interact with each other, and the strengths and limitations of their capabilities (physical, psychological, or otherwise). Applicants and licence holders should further consider how human factors will interact with technical and organisational factors.

Cognitive factors

Cognitive factors relate to how individuals process information, specifically, how they think, perceive, understand and respond to their environment. Understanding human information processing is key as this can impact safety, both directly and indirectly.

The following factors explain the components of human information processing, their role in safety, and the considerations necessary for managing it.

Situation awareness

Situation awareness refers to an individual’s ability to perceive a system’s current status, to anticipate its future status, and to respond appropriately (Endsley, 2015). Put more simply; ‘what is happening, what might happen next, and what can I do about it’. Good situation awareness allows individuals to respond appropriately and rapidly to changing circumstances, thereby supporting safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C5.3, C9.5, C17.3, C21.20, C21.23 |

Cognitive demands

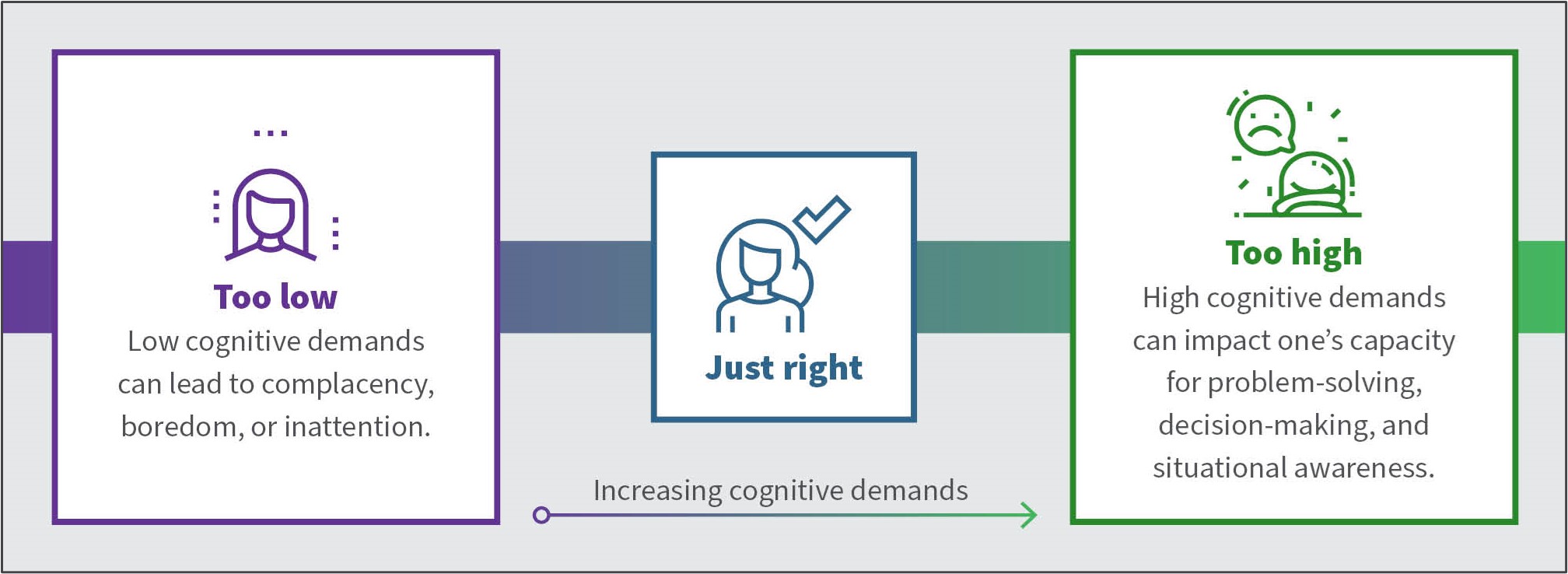

Cognitive resources like memory and attention are limited and in demand. Individuals rely on these resources to diagnose risks and to guide decision-making. As the complexity of a task increases, so too do cognitive demands. On either extreme, cognitive demands have considerable implications for safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C5.3, C9.5, C17.3, C21.20, C21.23 |

Cognitive demands

Cognitive resources like memory and attention are limited and in demand. Individuals rely on these resources to diagnose risks and to guide decision-making. As the complexity of a task increases, so too do cognitive demands. On either extreme, cognitive demands have considerable implications for safety.

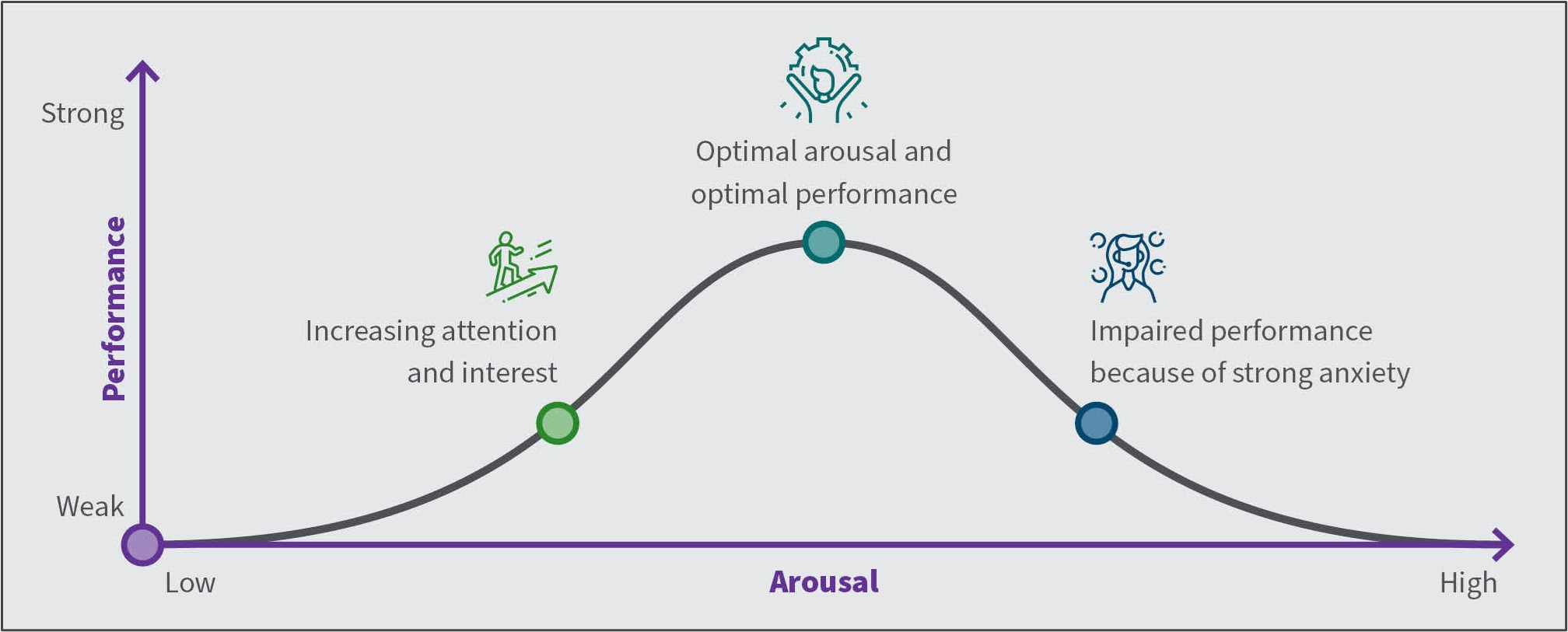

Figure 4: Balancing cognitive demands is key for optimal performance

Take for example, an operator who manages a control room with fully automated systems and where human intervention is rarely required. Over time, this operator may become inattentive, complacent or bored. Alternatively, operating a control room where systems are frequently and simultaneously in alarm and human intervention is frequently required may lead them to become overwhelmed, confused, or burnt out. Both cases can have cascading implications for situation awareness, decision-making, and safety overall.

When a task is novel, cognitive demands tend to be high as performance is based on the individual’s knowledge base (as there is no past experience to draw on). Over time, as individuals become more familiar and experienced, performance becomes more rule-based and skills-based, and cognitive demands decrease (Embrey, 2005; Rasmussen J. , 1983). If cognitive demands diminish too much, this can have negative safety implications.

Optimising cognitive demands to align with the mental capacities of the person conducting the work, and accounting for changes in demands over time, is key to safety performance.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C17.3, C33.7 |

| AUS/INT STDs | ISO 10075-1:2017, ISO 10075-2:2024, ISO 10075-3:2004 |

Sensory perception

Sensory perception refers to the use of senses (vision, hearing, touch, smell and taste) to perceive and understand the physical environment. Accurate perception is necessary for making informed decisions and taking appropriate action. Perceptual deficiencies or overstimulation (e.g. a loud working environment) can interfere with this accuracy, thereby impacting safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C17.3, C33.7 |

| AUS/INT STDs | AS/NZS 1269:2005, AS/NZS1680.2.4:2017 |

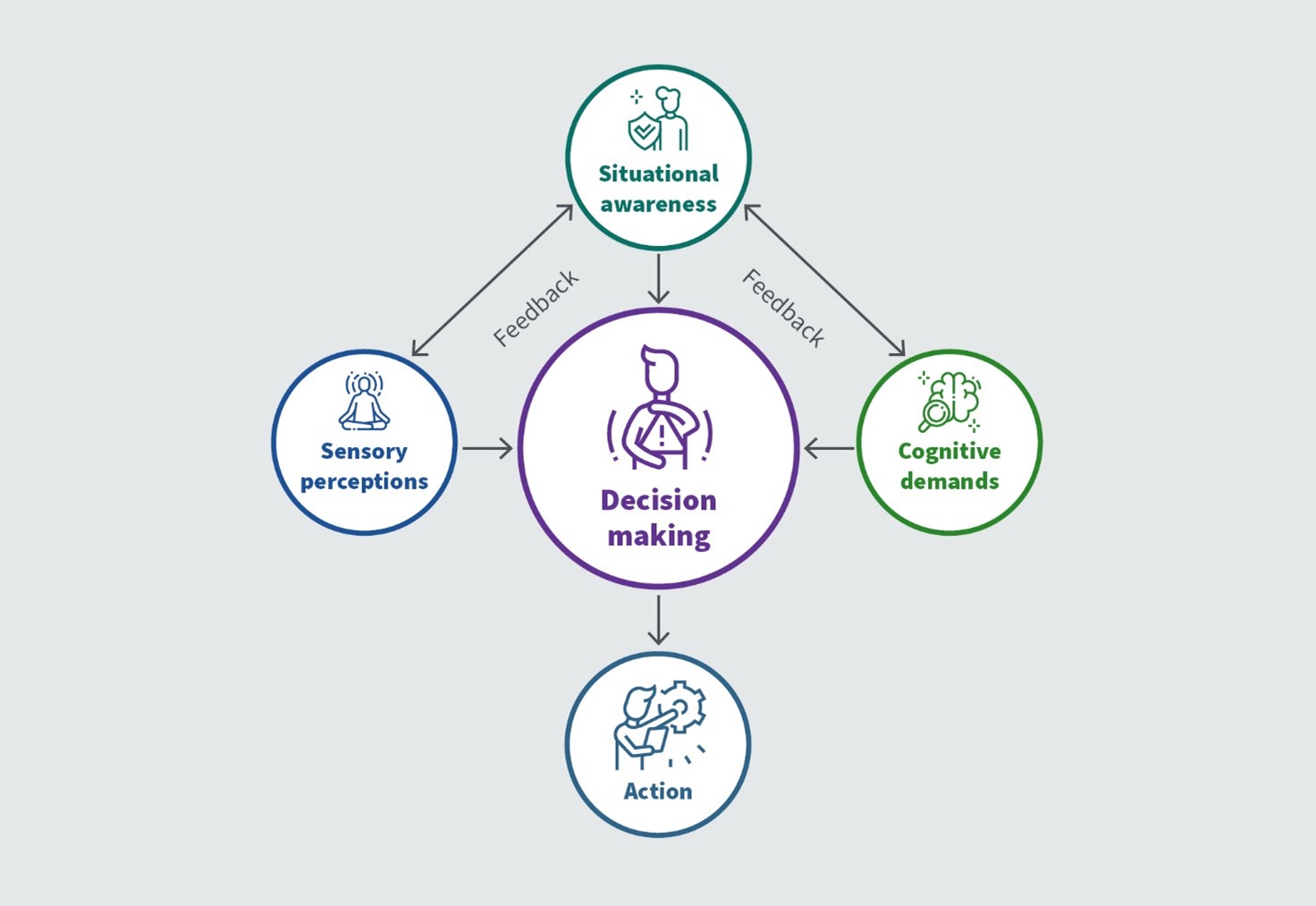

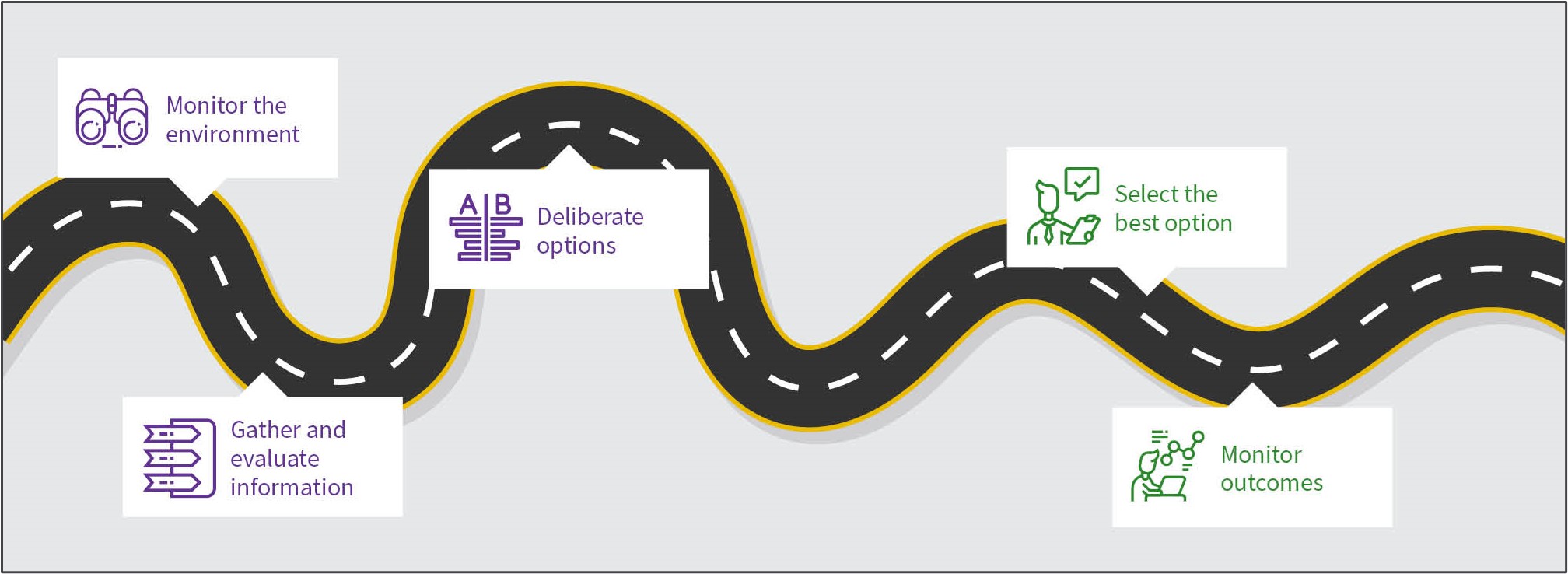

Decision-making

Decision-making is the process of reaching a judgement or choosing an option that meets the needs of a given situation. This can be done casually (intuitively) or analytically (through rational and logical evaluation) or even informed by technology (e.g. artificial intelligence).

Figure 5: Roadmap illustrating the journey of a good decision-maker

Decision-making, at both an individual and organisational level, should be appropriately conservative, realistic, and proportionate to the potential risks. Taking a conservative approach, where actions are determined to be safe before proceeding, benefits safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C14.2, C20.13, C34.3, C39.2 |

| GSR Part 2 | 3.1d, 3.3c, 4.7d, 4.9d, 4.10, 4.14, 4.17, 5.2g |

| HSCM | DM. |

Fitness for Duty factors

The factors within this category are those which may impact on both physical and psychological health and wellbeing. Organisations that adopt a holistic approach to the management of these factors protect safety outcomes by ensuring workers are fit for duty.

Stress and burnout

Stress is the high emotional arousal an individual might feel in response to a physically or cognitively challenging event. Some stress can be beneficial and help motivate individuals to rise to the occasion. This can support safety by promoting vigilance and other positive safety behaviour. However, stress can also become overly taxing on an individual’s physical or mental resources or exceed their ability to cope. This can degrade health and subsequently safety.

Figure 6: Relationship between arousal and performance

When individuals cope with stress by detaching from work, they are likely to be experiencing burnout. Burnout is a syndrome characterised by emotional exhaustion, increased mental distance from one’s job, and reduced feelings of personal accomplishment (World Health Organization, 2019).

Stress and burnout impact personal safety as well as one’s ability to uphold one’s safety and security responsibilities at work.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C17.3, C33.7 |

| GSR Part 2 | 6.3 |

| HSCM | PI, WP.1 |

| Other IBP | WHO/MNH/MND/94.21 |

Fatigue

Fatigue is a state of tiredness or diminished functioning. Fatigue can be both mental (e.g. complex decision-making), physical (e.g. physical exertion), or both (e.g. extended lack of sleep). Whilst individuals may be able to work through small amounts of fatigue, chronic fatigue can have increasingly dangerous effects on safety. The most insidious aspect of fatigue is that those who are fatigued often cannot recognise their own fatigue and thus, may continue to operate under these conditions. This can have considerable safety implications.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C17.3, C21.10, C33.7 |

| GSR Part 2 | 6.3 |

| HSCM | PI, WP.1 |

Psychosocial hazards

Psychosocial hazards are workplace factors which can cause psychological harm. These may arise from the design or management of work itself, the work environment, or workplace interactions. Psychosocial hazards can also interact to create new, changed, or more complex risks. For example, high workloads may become more hazardous when individuals also have insufficient breaks or poor peer support. Without intervention or controls, psychosocial hazards can impact safety (for example, by degrading decision-making or problem-solving abilities).

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C17.3, C21.10 |

| GSR Part 2 | 4.30, 5.2d |

| HSCM | PI, WP.1 |

| AUS/INT STDs | ISO 45003:2021 |

| Other IBP | Safe Work Australia Work-related psychological health and safety Safe Work Australia Managing psychosocial hazards at work |

Alcohol and other drugs

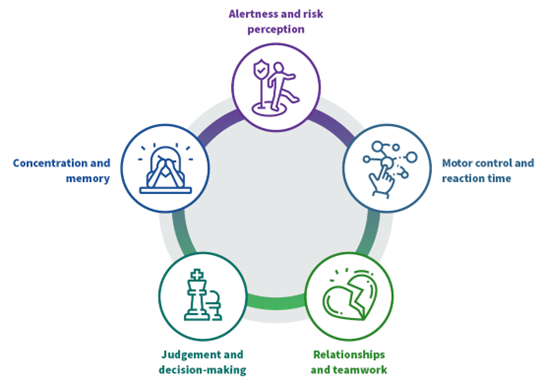

The effects of alcohol and other drugs (AOD) can impair one’s fitness for duty by degrading the physical and mental functions that are critical to safety. These include:

Figure 7: The effects of AOD

Identifying and managing staffs’ use of AOD is critical for reducing the risk of injury, harm and other negative safety outcomes.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C1.2, C5.4, C8.1, C8.2, C9.1 |

| HSCM | PI., RC. |

| Other IBP | Safe Work NSW Alcohol and other drugs in the workplace |

Physical ergonomics

The physical capabilities of an individual impact how they engage with equipment, tools, technology, tasks and the general work environment. The following sections outline the interplay between physical capabilities and safety and specifies the considerations necessary to ensure work environments are designed with consideration for those working within them.

Physical work environment

Physical work environment refers to the design of an individual’s and team’s workspace (e.g. desk, workbench) and the surrounding environmental conditions (e.g. lighting, noise, cleanliness). This can include the interactions between multiple workflows. Designing spaces to avoid unnecessary stresses and strains (e.g. postural risks and repetitive strain), whilst maintaining useability and accessibility, can help decrease the chance of error and enable safe practice.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C17 |

| GSR Part 2 | 2.2a, 2.2b |

| AUS/INT STDs | ISO 6385:2016, AS(/NZS) 2243 |

Anthropometry

Anthropometry is the measurement of the proportions, size and form of the human body, and the application of this information to the design of workspaces and equipment. Anthropometric design helps ensure that an individual’s full functional capacity is maintained when doing a task. For example, hazmat suits should adequately conform to an individual’s physical dimensions, or equipment at workstations should be easily accessible for individuals of different heights and limb lengths. Importantly, this requires a thorough understanding obtained via assessment of the actual user group.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C9.5, C15.3, C17.2, C17.3, C19.1, C19.2 |

| GSR Part 2 | 2.2a, 2.2b |

| AUS/INT STDs | ISO 6385:2016, ISO 7250-1:2017, AS 2243.1:2021 |

Chapter 3: Organisational factors

Organisations are complex structures, with individuals, teams and leadership working together with equipment, systems, and technology, inside a dynamic working environment, to uphold safety. This chapter outlines the importance of distinct organisational factors and their relevance to nuclear and radiation safety.

Licence holders should demonstrate a concerted effort to address these factors when developing the policies, processes, procedures and practices for their broader organisational systems. This includes thinking and responsive planning for the long-term. Addressing organisational factors should involve the consideration of their impacts and interactions with technical and human factors.

Workforce factors

The factors in the following section address an organisation’s ability to develop and ensure their workforce possesses the fitness, readiness, capacity, and capability to perform their work safely, as both individuals and as a team.

Competence and training

Competence is the collection of knowledge, skills and experience necessary for an individual to perform their duties to a recognised standard, including those set for safety and security. Having a competent workforce is crucial for safe operations.

Training (and assessment) is a key mechanism for ensuring that competence is achieved and maintained. Training involves updating, developing, applying and practising knowledge and skills. Together, competency and training help mitigate safety issues that may arise from a lack of knowledge and/or skills.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C12 |

| GSR Part 2 | Requirement 9 |

| HSCM | CL. |

| AUS/INT STDs | AS/NZS 45001:2018 7.2 |

| IBP | IAEA GSR Part 1: Requirement 11 |

Recruitment and resourcing

Recruitment and resourcing refer to the selection and acquisition of staff, including contractors and consultants. This requires an appropriate number of suitably qualified and experienced persons (SQEPs) who are equipped with the resources (budget, time, training, etc.) necessary to perform their duties safely. This includes taking a long-term view of the organisation, anticipating future needs, and planning accordingly.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C4.1, C4.2, C4.3, C12.2, C12.4 |

| GSR Part 2 | 4.21, 4.22, 4.23, 4.24, 4.27 |

| HSCM | LR.1 |

| IBP | IAEA-TECDOC-1917 IAEA Competency Assessments for Nuclear Industry Personnel. |

Communication

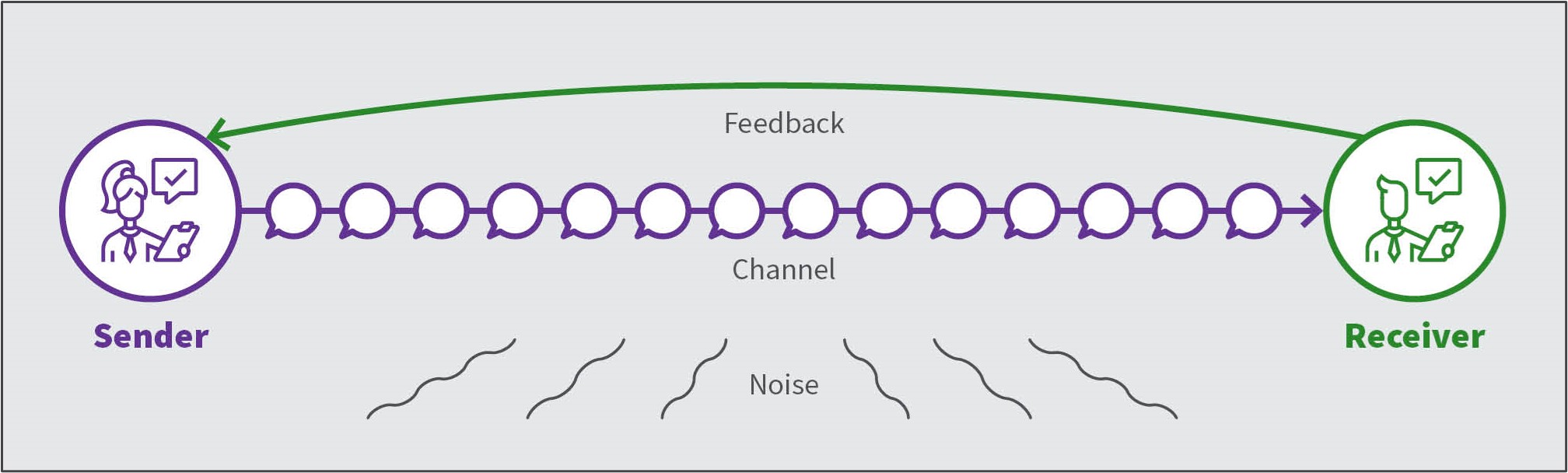

Communication is the interdependent exchange of information between parties, through speaking, writing, reading, listening, and remotely.

Figure 8: Good communication ensures a focus on safety, resulting in these outcomes

Effective communication can be a management aid for achieving shared meaning and driving safe performance. Ineffective communication can degrade safety by increasing the frequency and severity of errors. The effectiveness of communication depends on characteristics of the sender (e.g. clarity of message), characteristics of the receiver (e.g. receptiveness), and noise (e.g. distractions).

Figure 9: Effective communication is key to achieving shared meaning

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C5.1, C5.3, C10.4, C11.14, C12.3, C21.5 |

| GSR Part 2 | 4.7a, 4.7b, 5.2c |

| HSCM | CO., CL.3 |

| AUS/INT STDs | AS/NZS 45001:2018 7.4 |

Team Dynamics

Teams are groups of individuals, guided by a leader, working interdependently towards a common goal. The personal qualities, behaviours, styles and strategies adopted by both the individuals and the leader of a team influence safety. Leaders set the tone for safety by influencing norms, deciding on action, and allocating resources. This includes the leadership demonstrated by those outside of technical areas, as their example and decisions still impact upon safety. For example, a budgetary decision made by the CFO may apply a financial constraint that impacts the safety of work.

Groups that demonstrate good team dynamics can better adapt to adversity and solve more complex problems, thus supporting safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C5.3, C6.2, C12.2, C12.3, C15.4 |

| GSR Part 2 | 5.2a, 5.2c |

| HSCM | IR., CL.3, CL.4 |

| AUS/INT STDs | AS/NZS 45001:2018 5.4 |

Safety culture

Safety culture is the assembly of values, attitudes, and behaviour of individuals that result in and from a collective commitment to safety. This commitment establishes safety as the overriding priority within an organisation [26, 47].

Leadership for safety

Leadership significantly influences the safety culture of an organisation. The more senior a leader, the greater their influence on culture. This influence is exerted through the policies they enact, the example they set, and the expectations they place on their staff. ‘Leadership for safety’ acknowledges the considerable role of leaders in shaping culture and outlines the approach that should be adopted to demonstrate that safety is the top priority.

Figure 11: A visual representation illustrating the greater influence of more senior leaders in an organisation

Leadership for safety comprises:

- commitment to safety as a value

- responsibility and accountability

- communication, engagement and oversight.

Commitment to safety as a value

Leaders should hold, demonstrate, and institutionalise a strong commitment to safety as a core organisational value.

| Licence holders should demonstrate: |

|---|

|

Responsibility and accountability

It is important for leaders to understand, establish and adhere to their safety responsibilities and accountabilities.

| Licence holders should demonstrate: |

|---|

|

Communication, engagement and oversight

Leaders shall engage and communicate across their organisation and ensure adequate safety oversight.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C1.1, C1.5, C1.6, C2.1, C2.2, C2.3, C2.5, C5.1, C5.4, C8.2, C10.6, C36 |

| GSR Part 2 | Requirements 1, 2, 3, and 4 4.7, 4.16, 4.25, 4.33, 5.2a, 5.2c, 6.4, 6.5, 6.10, 6.11 |

| HSCM | LR, DM. 3, WE.3, RC.1 |

Individual responsibility

All individuals have a responsibility for safety, for both themselves and others. Individuals should feel a sense of ownership in knowing their safety responsibilities and striving to fulfil them.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C1.1, C1.2, C1.6, C8.2, C21.2 |

| GSR Part 2 | 3.1d, 3.2, 3.3, 4.25, 4.26, 5.2b |

| HSCM | IR. WE.2 |

Values and behaviour

A safe organisation will, at all levels, possess shared values and beliefs for safety. These values and beliefs produce and inform behavioural norms, which provide appropriate attention to safety and its prioritisation over competing goals.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C2.2, C2.3, C8.1, C21.16 |

| GSR Part 2 | 3.1, 3.2b, 5.1, 5.2 |

| HSCM | LR.1, LR.6, WE. |

Questioning attitude

A ‘questioning attitude’ is one where individuals are able and encouraged to question their work and working environment. This requires individuals to avoid complacency, remain vigilant, and voice concern even when the concern seems minor. This supports safety by identifying potential risks and taking action.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C10.8 |

| GSR Part 2 | 3.2c, 5.2e |

| HSCM | QA., RC. |

Just culture and fairness

A ‘just culture’ is one that acknowledges that errors are inevitable. Errors reflect a wider system of failures rather than a failure of the individual. A just culture balances safety and accountability (Dekker, 2007) by fairly distributing rewards and sanctions. Individuals are encouraged to continue reporting issues, even when linked to their own actions. This satisfies the need for accountability and provides an opportunity for learning and improvement.

Fairness requires a consistent approach to be taken in the rewarding, sanctioning and general treatment of all staff. This is key to building a just culture.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C10.3 |

| HSCM | LR.6, WE., RC. |

Management systems

A comprehensive definition of management systems can be found in ARPANSA’s Regulatory Guide - Plans and arrangements for managing safety (ARPANSA-GDE-1735). Management systems are relevant to holistic safety due to their ability to influence an organisation’s safety culture, and for this safety culture to influence management systems in return. Management systems are the key location of the information required to conduct work safely.

Procedure management

Procedure management refers to the foundational role of documented procedures in supporting safety. When properly implemented, these procedures offer a consistent, risk-assessed approach to work. Procedures that accurately reflect work-as-done, and are adhered to, contribute meaningfully to achieving safety objectives. Importantly, effective procedure management requires the support of underlying policies and processes, as well as good document management practices. Good oversight over, and periodic updates of, documents including creation, maintenance, management, and use of documents can safeguard against risks to safety.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| ARPANS Regulations | s76, s81 |

| POCs(F) | C6.2, C7, C8.3, C12.20, C17.3, C18, C19.3, C20.5, C33.1, C33.10 |

| GSR Part 2 | 4.28, 4.29, 4.32, 6.2, 6.3, Requirement 8 and 10 |

| HSCM | WP.3 |

| AUS/INT STDs | ISO 9001:2015 |

| IBP | ARPANSA Regulatory Guide - Plans and arrangements for managing safety |

Change management

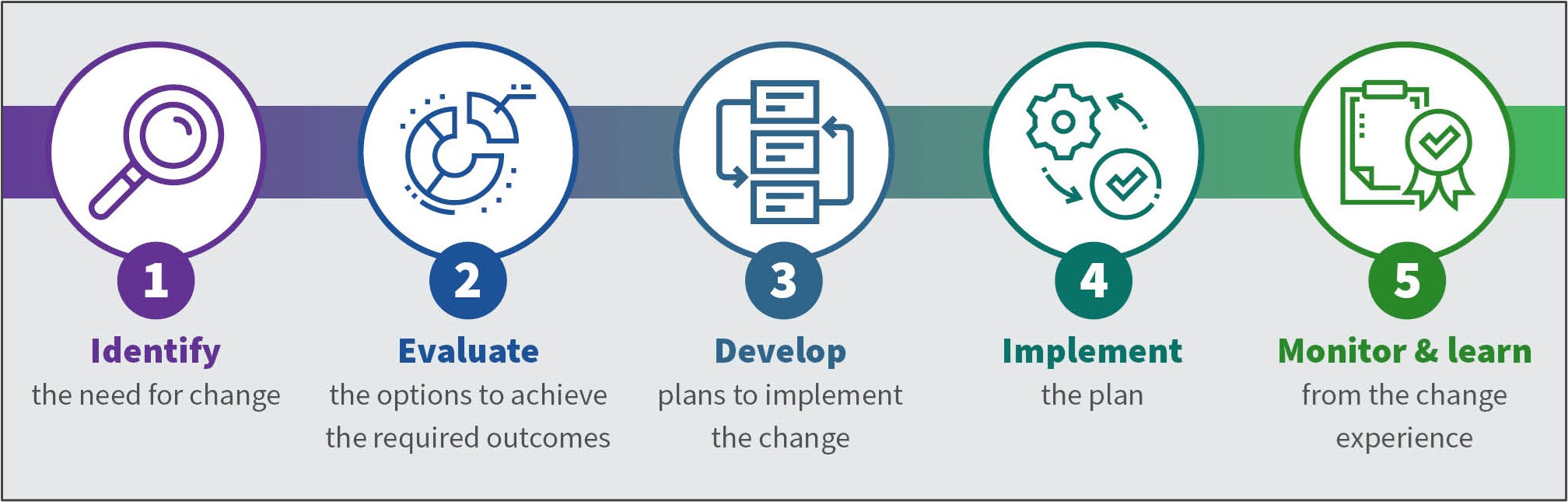

Change management is the process of undertaking change in a systematic and methodical way. Good change management maintains safety throughout all phases of the change. A typical change management process involves the following steps:

Figure 10: The change management process

These steps should be followed diligently to ensure that changes have no detrimental effects on safety.

Where a change has significant implications for safety, licence holders require prior approval from the CEO of ARPANSA under section 63 of the Regulations. Thresholds for when and how to seek approval can be found within ARPANSA’s Regulatory Guide - When to seek approval to make a change with significant implications for safety (ARPANSA-GDE-1751).

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| ARPANS Regulations | s61(2), 63 |

| POCs(F) | C6.3, C11 |

| GSR Part 2 | 4.13 |

| HSCM | LR.4, LR.7, CL.3 |

| IBP | IAEA-TECDOC-1226 |

Project management

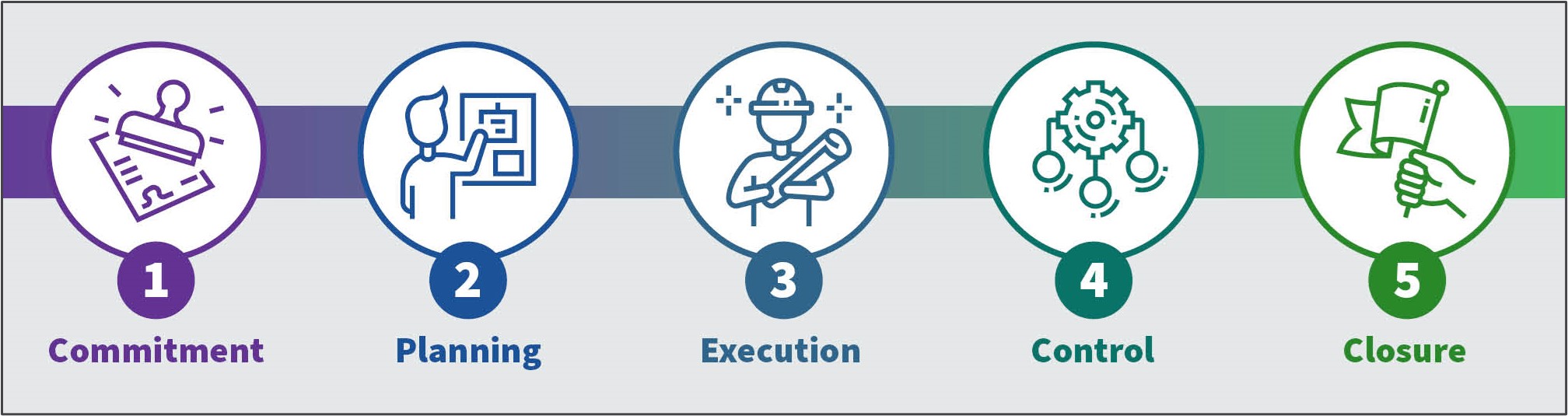

Project management is the application of knowledge, skills, tools and techniques, to plan activities that meet the needs of a project. A project typically spans 5 phases:

Figure 11: The typical timeline of a project

Managing safety is an integral part of project management and interacts with all phases of the project lifecycle. Making safety considerations early in the project planning phase may offer the greatest protection to safety outcomes.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C1.1, C6.4, C8.3, C9.1 |

Contractor management

Calling upon the expertise of external service providers is often necessary. However, the use of contractors (incl. consultants) can introduce safety risks when improperly managed. Having a robust contractor management system can help mitigate these risks. This system should put in place arrangements that specify, monitor, and manage contractors in a way that aligns with the safety standards of the organisation.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C1.4, C1.5, C1.6, C5.1, C7.3, C21.6 |

| GSR Part 2 | Requirement 11 |

Chapter 4: Systemic factors

This category addresses broader factors which should be integrated into all systems across an organisation. The absence of these factors may signal an incomplete or potentially unsafe organisational system.

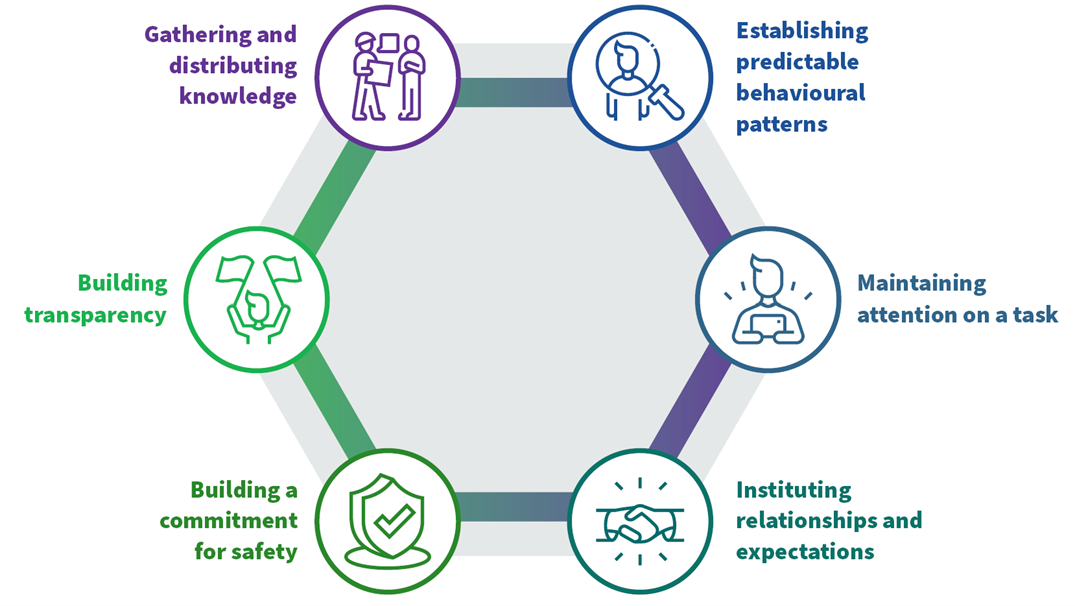

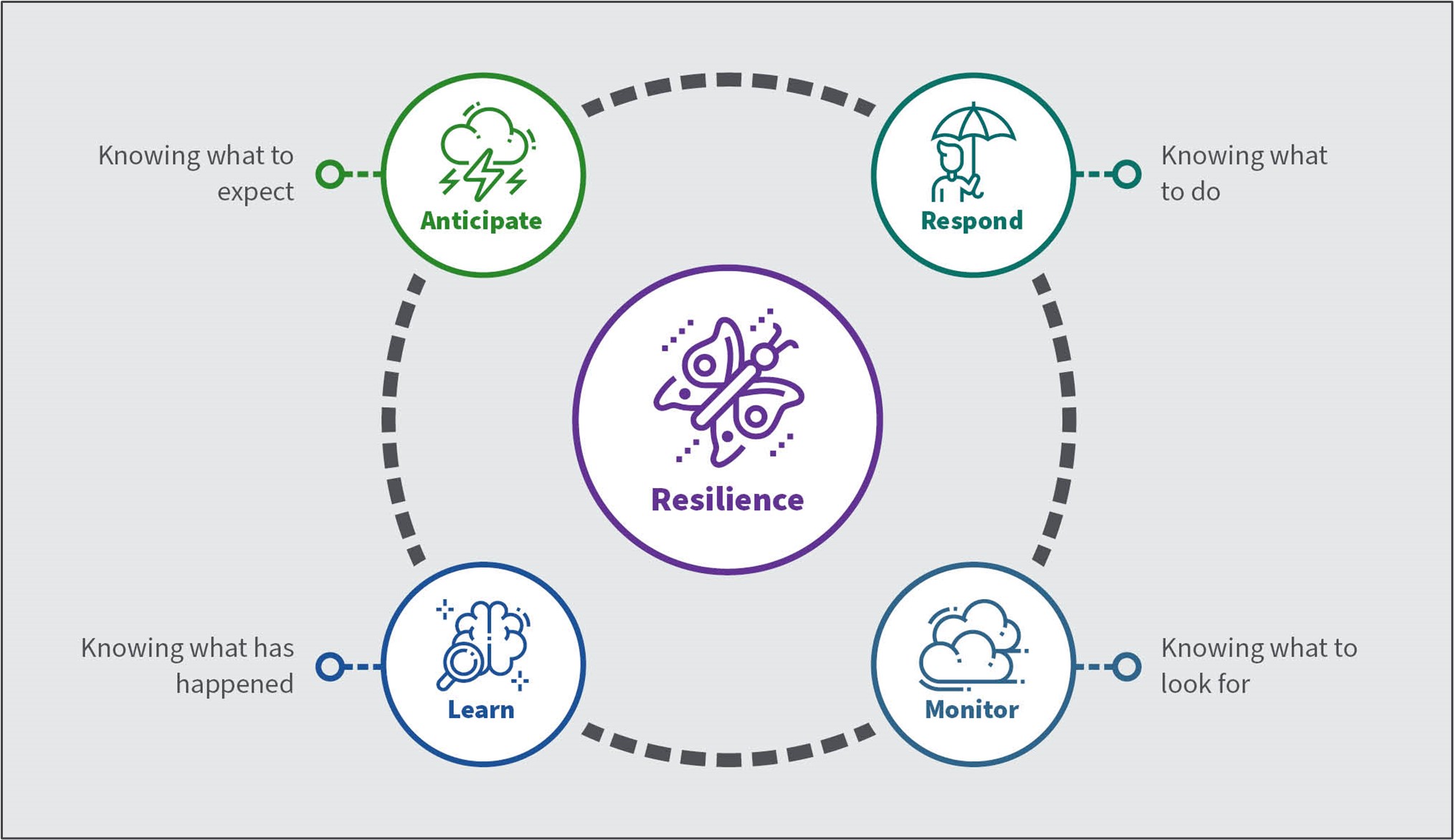

Resilience

Resilience refers to a set of abilities that enable a system to maintain or regain a safe and stable state. Systems achieve this by adjusting themselves before, during or after an event, and continuing to operate safely in both expected and unexpected conditions.

A resilient system is one which has the ability to respond, monitor, learn and anticipate (Hollnagel, 2010)

Figure 12: The abilities which enable strong resilience

The ability to respond

The ability to respond involves taking appropriate action to maintain or regain a safe and stable system state. This requires individuals to know what to do to adjust to both expected and unexpected conditions, including when to enact planned actions.

| Licence holders should demonstrate: |

|---|

|

The ability to monitor

The ability to monitor involves identifying and keeping track of indicators that help determine the safety and stability of a system. This includes indicators which both positively and negatively impact upon safety. Importantly, a long-term approach to monitoring is crucial, particularly in recognising slow, incremental changes that could have significant safety implications over time (i.e. drift; Dekker, 2011).

| Licence holders should demonstrate: |

|---|

|

The ability to learn

The ability to learn involves taking stock of past events, generating insights and lessons learnt, and understanding and leveraging these lessons to improve systems. The effectiveness of learning is impacted by which events are captured, how well they are analysed, and how meaningful the derived lessons are.

| Licence holders should demonstrate: |

|---|

|

The ability to anticipate

The ability to anticipate involves forecasting for potential events, conditions, threats or opportunities that may either benefit or hinder the safety and stability of systems. Furthermore, it involves making plans and preparations to address them.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| ARPANS Regulations | s57B, s58, s61 |

| POCs(F) | C6.1, C7.1, C7.2, C8.1, C9.4, C10, C11.1, C13, C14.5, C20, C22, C32.5, C32.21, C32.22, O7, O8 |

| GSR Part 2 | 5.2(e), Requirement 13 and 14 |

| HSCM | DM.4, WP.2, PI. |

| IBP | IAEA GSR Part 7 Emergency Preparedness and Response |

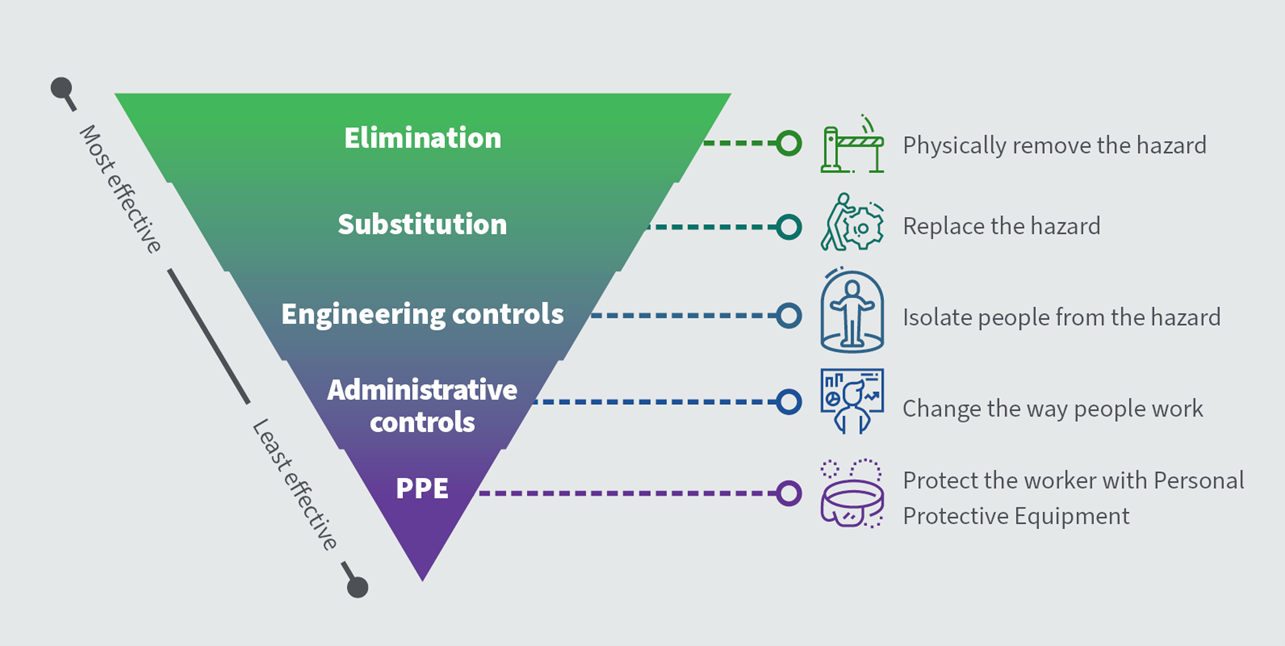

Hierarchy of Controls

The Hierarchy of Controls (HoC) is a sequential approach to managing risk, arranged from most to least effective. Employing the highest level of control (elimination) is desirable and encouraged. However, this may not always be practicable. In this case, subsequent levels of control should be implemented. Effective protection will often involve the deployment of multiple controls across the hierarchy, with resources prioritised for controls higher in the hierarchy (e.g. engineering controls such as interlocks must be supported by maintenance and inspections procedures to effectively manage safety).

Selecting which controls to deploy will require a thorough understanding of the people performing the work, the technologies they use, and the environment within which they operate. Importantly, controls must be visible and well understood by workers to be effective. Otherwise, they are routinely violated and often fail.

Figure 13: The hierarchy of controls demonstrates the various ways in which risk can be mitigated

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C6.3, C9.1, C9.5, C13.10, C17.1, C19, C37.1 |

| AUS/INT STDs | ISO 45001:2018 |

User-centred design

User-centred design (UCD) places the end user at the centre of the design process. This helps designers understand (and design to) the needs of the end user, the work they do, and their work environment. Safety can degrade when design does not appropriately account for the real-life use cases of end users. For example, having touchscreen equipment in a lab where workers are wearing protective gloves, rendering the touchscreen unusable. UCD addresses this by encouraging users to participate in the design process upfront, thus helping protect systems from the threats of traditional design methods.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| POCs(F) | C6.2, C7.1, C17.2, C17.3, C21.10 |

| GSR Part 2 | 2.2a, 2.2b, 5.2d |

| AUS/INT STDs | ISO 9241-220:2019 |

Security

Security is an essential part of safety, where any controlled source, apparatus or facility can only be considered safe if it is also secure.

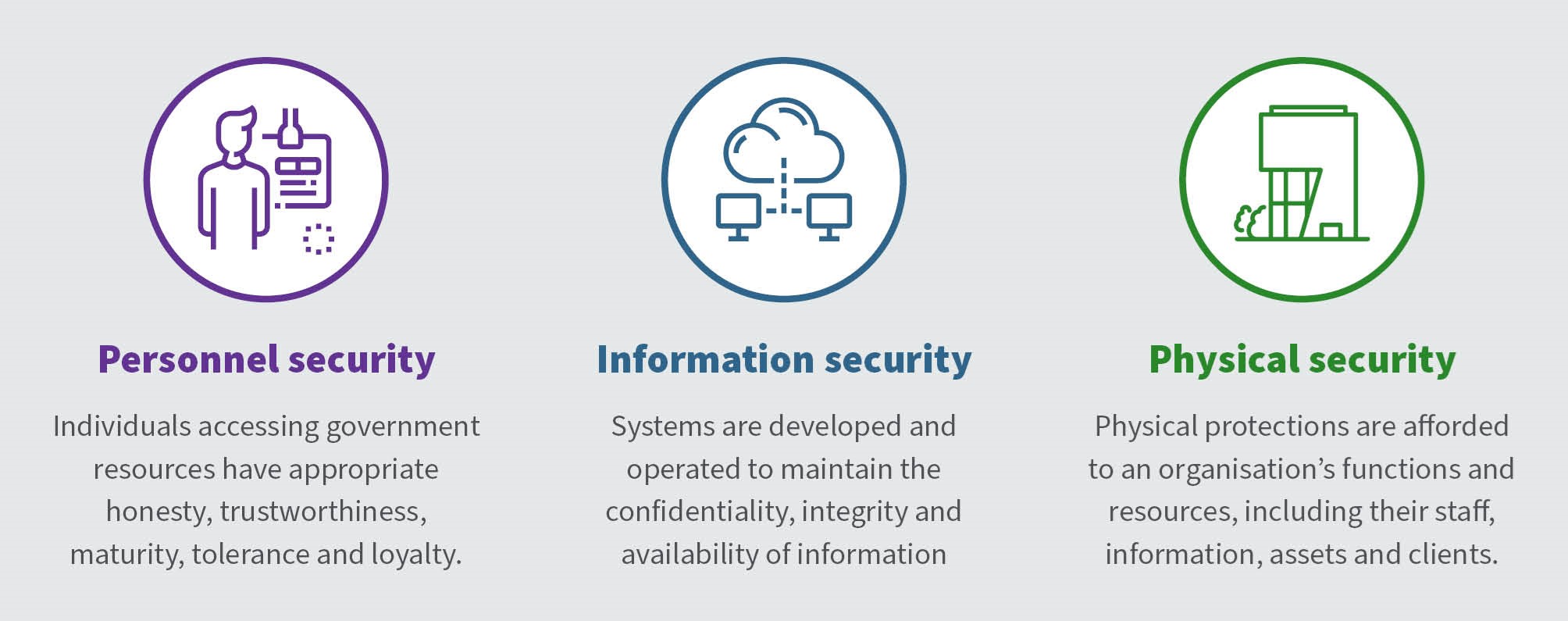

Security Integration

Security concerns the implementation of systems and a culture which supports:

The common aim for these different forms of security is to mitigate the potential harm caused intentionally by bad actors, or inadvertently by good actors, to themselves or others.

Nuclear Security Culture

Nuclear security culture refers to the assembly of characteristics, attitudes and behaviours of individuals, organisations and institutions, which serve to support and enhance nuclear security. Whilst safety culture and security culture share common goals, security culture places additional emphasis on deliberate acts that are intended to cause harm. For this reason, a different set of attitudes and behaviour are required to establish a good security culture.

Safety-Security Intersection

At times, safety and security may be competing priorities. To ensure safety remains the overriding priority, without jeopardising security, it is important to understand and manage where safety and security intersect.

| Licence holders should demonstrate: |

|---|

|

| This factor is relevant to: | Reference: |

| ARPANS Regulations | s57c |

| POCs(F) | C1.6, C2.2, C4.1, C10.2, C29, O6 |

| GSR Part 2 | 4.10, 4.15b, 5.2h |

| HSCM | PI.1 |

| IBP | ARPANSA RPS No. 11 |

For more information, see ARPANSA’s Radiation Protection Series No. 11 Code of Practice for the Security of Radioactive Sources (2019) and the Plans and Arrangements for Managing Safety Regulatory Guide.

Glossary

Note: Definitions for each factor included in this Guide are provided at the beginning of their respective sections.

Accountability

Being answerable for safety outcomes due to holding ownership over a system and its risks.

Contractor

A worker who is external to the licence holder’s organisation, but who performs work on behalf of the licence holder.

Constraint

Any system element that imposes limits on other parts of the system. These limits could be on resourcing, finances, time, radiation dose, etc.

Continuous improvement

The ongoing process of identifying, analysing, and making incremental improvements to systems, processes, procedures, and practices.

Control

An element of, or change in, design which intends to eliminate or mitigate the risk of adverse events.

Coupling

The degree of interdependence that exists between system elements. Tight coupling between system elements may allow for cascading failures through the system. Loose coupling may reduce control over the system.

Graded approach

An approach where the scale of actions taken is proportional to the significance of the risk

Holistic safety/holistic approach

A best-practice approach which considers technical, human and organisational factors, including how factors interact and the relationships between them.

Incidents, near misses and deviations

Incident - the Regulations state that an “incident means:

(a) any unintended event, including an operating error, equipment failure, initiating event, accident precursor, near miss or other mishap; or

(b) any unauthorised act, whether or not malicious;

the consequences or potential consequences of which are not negligible.”

Near miss - an incident in which no harm was done to individuals or the environment, but where these consequences were narrowly avoided due to controls failing, or not being present.

Deviation - Any circumstance which results in a departure from normal conditions. A deviation may or may not result in an incident. For example, an authorised departure from procedure which results in no adverse consequences is still considered a deviation.

Heuristics

Mental short-cuts or rules of thumb which are less cognitively demanding but may oversimply a situation or event.

Intelligent Customer

The capability of the organization to have a clear understanding and knowledge of the product or service being supplied. The ‘intelligent customer’ concept relates mainly to a capability required of organizations when using contractors or external expert support.

Management system

The systems, tools and processes that allow for effective record-keeping, information availability and quality assurance, particularly during periods of development and change.

Performance

The extent to which a person is capable of carrying out a task or process safely and successfully.

Safety

Safety is the ability to perform work in varying, unpredictable environments without causing harm. This is demonstrated by the presence of defences, not the absence of accidents.

System

A set of dynamically interacting elements. These elements include technologies, organisational structures and people.

This guide refers to multiple systems.

Systems-thinking

An approach which considers systems as a whole and emphasises the interactions and relationships between elements of the system. This often involves the consideration of a hierarchy which groups system elements in to work design, frontline staff, management, the organisation, and external elements (including government, regulators and the public).

Work-as-done

The way in which work is actually performed, rather than the way it is expected to be done when planning (work-as-planned).

References

Australasian Faculty of Occupation and Environmental Medicine. (2011). Australian Consensus Statement on the Health Benefits of Work. Retrieved from https://www.acrrm.org.au/docs/default-source/all-files/aust-consensus-s…

Australian Government Department of Industry, Science and Resources. (2024). Voluntary AI Safety Standard. Retrieved from https://www.industry.gov.au/sites/default/files/2024-09/voluntary-ai-sa…

Australian Radaition Protection and Nuclear Safety Agency. (2019). Radiation Protection Series No. 11: Code of practice for the security of radioactive sources. Retrieved from https://www.arpansa.gov.au/sites/default/files/rps11.pdf

Australian Radaition Protection and Nuclear Safety Agency. (2019). Safety Culture Assessments. Retrieved from https://www.arpansa.gov.au/regulation-and-licensing/regulation/regulato…

Australian Radaition Protection and Nuclear Safety Agency. (2023). Regulatory Guide - Plans and arrangements for managing safety (ARPANSA-GDE-1735). Retrieved from https://www.arpansa.gov.au/regulation-and-licensing/licensing/informati…

Australian Radaition Protection and Nuclear Safety Agency. (2024). Regulatory Guide - When to seek approval to make a change with significant implications for safety (ARPANSA-GDE-1751). Retrieved from https://www.arpansa.gov.au/regulation-and-licensing/licensing/informati…

Australian Radiation Protection and Nuclear Safety Act 1998 (Cth).

Australian Radiation Protection and Nuclear Safety Regulations 2018 (Cth).

Badri, A., Gbodossou, A., & Nadeau, S. (2012). Occupational health and safety risks: Towards the integration into project management. Safety Science, 50(2), 190-198. doi:https://doi.org/10.1016/j.ssci.2011.08.008

Civil Aviation Safety Authority Australia. (2013). Safety behaviours: Human factors resource guide for engineers. Retrieved from https://www.casa.gov.au/sites/default/files/2021-06/safety-behaviours-h…

Conklin, T. (2012). Pre-accident investigations: an introduction to organizational safety. Ashgate.

Dekker, S. (2007). Just Culture. Ashgate Publishing Company.

Dekker, S. (2011). Drift into failure. Ashgate.

Embrey, D. (2005). Understanding human behaviour and error. Retrieved from https://mail.humanreliability.com/articles/Understanding%20Human%20Beha…

Endsley, M. (2015). Situation Awareness Misconceptions and Misunderstandings. Journal of Cognitive Engineering and Decision Making, 4-32. doi:10.1177/1555343415572631

Flin, R., O'Connor, P., & Crichton, M. (2008). Safety at the sharp end: A guide to non-technical skills. CRC Press. doi:https://doi.org/10.1201/9781315607467

Hollnagel, E. (2010). Resilience engineering in practice: a guidebook. Ashgate.

Interantional Atomic Energy Agency. (2016). Leadership and Management for Safety - General safety requirements No. GSR Part 2. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1750web.pdf

Interantional Atomic Energy Agency. (2016). Performing safety culture self-assessments - Safety report series No. 83. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1682_web.pdf

Interantional Atomic Energy Agency. (2020). A Harmonized Safety Culture Model. Retrieved from https://www.iaea.org/sites/default/files/20/05/harmonization_05_05_2020…

Internationa Organization for Standardization. (2016). Ergonomics principles in the design of work systems. (ISO 6385:2016). Retrieved from https://www.iso.org/standard/63785.html

International Atomic Energy Agency. (1991). Safety culture. Safety series No,75-INSAG-4. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub882_web.pdf

International Atomic Energy Agency. (1996). Defence in depth in nuclear safety - INSAG-10. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1013e_web.pdf

International Atomic Energy Agency. (2002). Key practical issues in strengthening safety culture - INSAG-15. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1137_scr.pdf

International Atomic Energy Agency. (2014). Managing organizational change in nuclear organizations. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1603Web-32823532.pdf

International Atomic Energy Agency. (2016). Safety of nuclear plants: Commissioning and operation. Specific Safety Requirements No. SSR-2/2. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1716web-18398071.pdf

International Atomic Energy Agency. (2018). Organization, management and staffing of the regulatory body for safety - General safety guide No. GSG-12. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/P1801_web.pdf

International Atomic Energy Agency. (2018). Organization, management and staffing of the regulatory body for safety - General Safety Guide No. GSG-12. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/P1801_web.pdf

International Atomic Energy Agency. (2020). Assessing behavioural competencies of employees in nuclear facilities. Retrieved from https://www.iaea.org/publications/14694/assessing-behavioural-competenc…

International Atomic Energy Agency. (2020). Assuring the competence of nuclear power plant contractor personnel - IAEA-TECDOC-1232/Rev.1. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/TE-1232_Rev1_web.pdf

International Atomic Energy Agency. (2023). The operating organization and the recruitment, training and qualification of personnel for research reactors - Specific safety fuide No. SSG-84. Retrieved from https://www-pub.iaea.org/MTCD/Publications/PDF/PUB2048_web.pdf

International Organanization for Standardization. (2015). Quality management systems - requirements. (ISO 9001:2015). Retrieved from https://www.iso.org/standard/62085.html

International Organization for Standardization. (2004). Ergonomic prinicples related to mental workload. Part 3: Principles and requirements concerning methods for measuring and assessing mental workload. (ISO 10075-3:2004). Retrieved from https://www.iso.org/standard/27571.html

International Organization for Standardization. (2017). Ergonomic principles related to mental workload. Part 1: General issues and concepts, terms and definitions. (ISO 10075-1:2017). Retrieved from https://www.iso.org/standard/66900.html

International Organization for Standardization. (2018). Occupational health and safety management systems - requirements with guidance for use. (ISO 45001:2018). Retrieved from https://www.iso.org/standard/63787.html

International Organization for Standardization. (2021). Occupational health and safety management - psychological health and safety at work - guidelines for managing psychosocial risks. (ISO 45003:2021). Retrieved from https://www.iso.org/standard/64283.html

International Organization for Standardization. (2022). Information and documentation - management systems for records - guidelines for implementation. (ISO 30302:2022). Retrieved from https://www.iso.org/standard/81595.html

International Organization for Standardization. (2024). Ergonomic principles related to mental workload. Part 2: Design principles. (ISO 10075-2:2024). Retrieved from https://www.iso.org/standard/76686.html

International Organization for Standardization. (n.d.). Ergonomics of human-system interaction ISO 9241 (multiple parts).

National Aeronatuics and Space Administration. (2022). Anthropometry, biomechanics, and strength - OCHMO-HB-004. Retrieved from https://www.nasa.gov/wp-content/uploads/2015/03/ochmo-hb-004_october_20…

Office for Nuclear Regulation. (2014). Safety assment principles for nuclear facilities. Retrieved from https://onr.org.uk/media/pobf24xm/saps2014.pdf

Rasmussen, J. (1983). Skills, Rules, and Knowledge; Signals, Signs, and Symbols, and Other Distinctions in Human Performance Models. IEEE Transactions on Systems, Man, and Cybernetics, 257-266. Retrieved from https://static1.squarespace.com/static/53b78765e4b0949940758017/t/5728a…

Rasmussen, J. (1997). Risk management in a dynamic society: a modelling problem. Safety Science, 27(2-3), 183-213. doi:https://doi.org/10.1016/S0925-7535(97)00052-0

Safe Work Australia. (2019). Work-related psychological health and safety: A systematic approach to meeting your duties. Retrieved from https://www.safeworkaustralia.gov.au/system/files/documents/1911/work-r…

Safe Work Australia. (2022). Managing psychosocial hazards at work: Code of practice. Retrieved from https://www.safeworkaustralia.gov.au/sites/default/files/2022-08/model_…

Safe Work NSW. (2006). Alcohol and other drugs in the workplace: Guide to developing a workplace alcohol and other drugs policy. Retrieved from https://www.safework.nsw.gov.au/__data/assets/pdf_file/0003/49962/drugs…

Salmon, P., Hulme, A., Walker, G., Waterson, P., & Stanton, N. (2023). Towards a unified model of accident causation: refining and validating the systems thinking safety tenets. Ergonomics, 66(5), 644-657. doi:https://doi.org/10.1080/00140139.2022.2107709

Säteilyturvakeskus Radiation and Nuclear Safety Authority. (2019). Leadership and management for safety - Guide YVL A.3. Retrieved from https://finlex.fi/api/media/authority-regulation/545809/mainPdf/main.pd…

Taylor, R., van Wijk, L., May, J., & Carhart, N. J. (2015). A study of the precursors leading to ‘organisational’ accidents in complex industrial settings. Process Safety and Environmental Protection, 93(2015), 50-67. doi:https://doi.org/10.1016/j.psep.2014.06.010

Wiggins, M. (2022). Introduction to human factors for organisational psychologists. CRC Press.

World Association of Nuclear Operators. (2013). Traits of a Healthy Nuclear Safety Culture - PL 2013-1. Retrieved from https://www.wano.info/wp-content/uploads/2024/07/WANO-PL-2013-1-Pocketb…

World Health Organization. (1994). Guidelines for the primary prevention of meantal, neurological and psychosocial disorders - 5. Staff burnout. Retrieved from https://iris.who.int/bitstream/handle/10665/60992/WHO_MNH_MND_94.21.pdf…

World Health Organization. (2019). Burn-out an "occupational phenomenon: Interantional classificaiton of diseases. Retrieved from https://www.who.int/news/item/28-05-2019-burn-out-an-occupational-pheno…